A project ongoing in Quincy, IL illustrates how a well-built manufacturing facility will help a company implement new technology, make new products and increase quality and efficiency.

The Korte Company is hard at work on the construction of such a facility for The Knapheide Manufacturing Company. The maker of truck bodies and beds has serious roots in Quincy—they started building their first wagons in the Gem City in 1848.

When it’s all said and done, Knapheide intends to add up to 60 new jobs at the new site initially. As many as 150 new employees will work there at full capacity.

Increasing production capacity

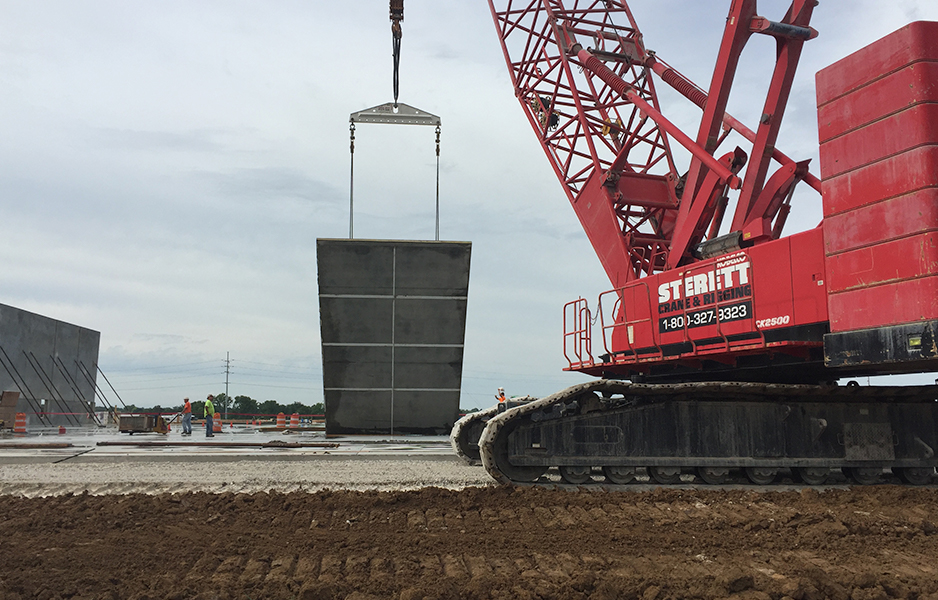

Growth motivated Knapheide’s decision to build what will eventually become 178,000 square feet of new manufacturing space and 10,000 square feet of offices.

The facility will house production of an entirely new product line using new manufacturing technology that Knapheide says will increase their productivity and the quality of the products they make.

The facility will feature state-of-the-art digital lighting, insulation and air handling all meant to meet stricter energy code requirements and save on long-term energy costs.

With deep roots in the Quincy area, it was important to Knapheide to employ local subcontractors for the job. We know a bit about deep roots ourselves, and strive to build strong relationships with subs anywhere we build. We’re happy to oblige.

Fighting the weather

Anyone in the business knows foul weather gets in the way. That’s why it’s so critical to take advantage when conditions are ripe for building.

It’s what happened on the Knapheide site. We got a good jump on the project, breaking ground in February 2017. In winter in western Illinois, that’s normally impossible.

That head start was critical: Even with two dozen or so bad weather days since then, we’re still on target to meet our March 1, 2018 deadline.

Experienced Design-Builder

The Korte Company has done jobs like this before. A lot of them. In fact, Knapheide is a repeat customer—we built a similar manufacturing facility for them 20 years ago.

Our experience for industrial jobs like this has helped us develop best practices that Knapheide leaders say they appreciate:

- We’ve got on-site management down to a science. From what’s been done to what’s left to do, we’re on top of it all, all the time.

- Progress reports are a big deal. Owners in any industry need to keep a close eye on how things are going at the jobsite. We make that easy by sharing project updates frequently via email, app or an old-fashioned phone call.

- Using cutting-edge estimation technology has been a game-changer. Using new estimation tech on each job lets us work together with customers to take some of the uncertainty out of each job.

- On these jobs, it’s about safety, no matter what. Our safety experts take their work seriously, conducting safety meetings as often as necessary—sometimes every day.

- It’s simple: Keep lines of communication open. The work of getting a new building off the ground is hard enough. We’re here to make construction easy.

Industrial facilities often are the most important assets a company has. Your contractor should treat your project with that in mind. Download the guide below for more about choosing your manufacturing facility builder.

“I can’t over-emphasize the on-site professionalism of The Korte Company. One of the things I’m most impressed with is their management of contractors. They have contractor meetings frequently if not daily. And they prioritize safety—nobody goes on site without going through a safety orientation. Their on-site management is exceptional.” – Harry Marcionetti, Senior Vice President of Operations, Knapheide Manufacturing Company.